Nomination for the 20th century’s wonder of the industrial revolution will certainly be bagged by ‘Additive Manufacturing’. Additive Manufacturing (AM) needs to be seriously evaluated as a complement to existing and traditional manufacturing methods.

An overview of Subtractive Manufacturing

The traditional subtractive manufacturing continues to dominate major production and assembly lines such as automobiles, FMCG, electronics and many more.

In subtractive manufacturing, you start with a hunk of material. The unwanted material is removed from this hunk bit-by-bit until you reach the final shape. Subtractive manufacturing depends heavily on the use of CNC (Computer Numerical Control)machines. CNC machines allow the required shape of the product to be programmed by a computer. This programming data enables the operations to be done repeatedly over and over again.

There are a lot of subtractive manufacturing approaches and methods. But milling and turning are the most common. A CNC mill has a rotary tool, that cuts away metal, wood, foam and any other material forming the final product.

Turning is done using a lathe. Here you spin the part into a stationary cutter while erosion and grinding are used for removing smaller amounts of material.

The limitations of cutting and drilling technology severely restricts the creation of hollow parts from a single piece. It also restricts the number of details that can be created with a single tool. Despite these technical limitations, subtractive manufacturing delivers precision.

In subtractive manufacturing, air costs money. Meaning, when the material has to be removed from the original stock, cycle time is incurred and thus money.

The complexity is limited to what can be removed. Subtractive is better when the amount of material to be removed from the stock is relatively little. A block with few holes or features is typically much cheaper to machine.

The traditional manufacturing method has ceased to be innovative lately. Additive manufacturing has made its entry and has set the market on fire with its never ending advantages. Additive certainly promises to overcome the drawbacks of subtractive manufacturing, but it won’t replace the latter. Let us now take a look at additive from the revolutionary point of view.

As a Mechanical Engineering graduate, it is obvious for us to look at valid reasons to replace the trust in traditional manufacturing. The newer technology has to withstand the market forces at play.

A success story when AM was used to save a life :

A 32-year-old woman with tuberculosis of the spine suffered severe damage to her first, second and third cervical vertebrae, threatening her with paralysis and even death. She had no support between her skull and lower spine. The disease had caused such extensive damage that surgery could not fix. Coupled with that, she had a lowered immune system caused by drugs which she was taking for infertility. The only option was to support the skull and vertebral column with some rigid replica of the bones structure. A team of surgeons decided to experiment using a titanium implant, customised to perfectly fit her spine. They replaced her damaged vertebrae with a 3D printed implant. This 3D printed implant was tested for biomechanics and stress risers, with input from multiple design teams. And when everybody around had lost hopes of her recovery, 3D printed implant proved a boon and saved her life!

Here let us try to decode AM and take a better look at it.

Additive Manufacturing

What is Additive Manufacturing?

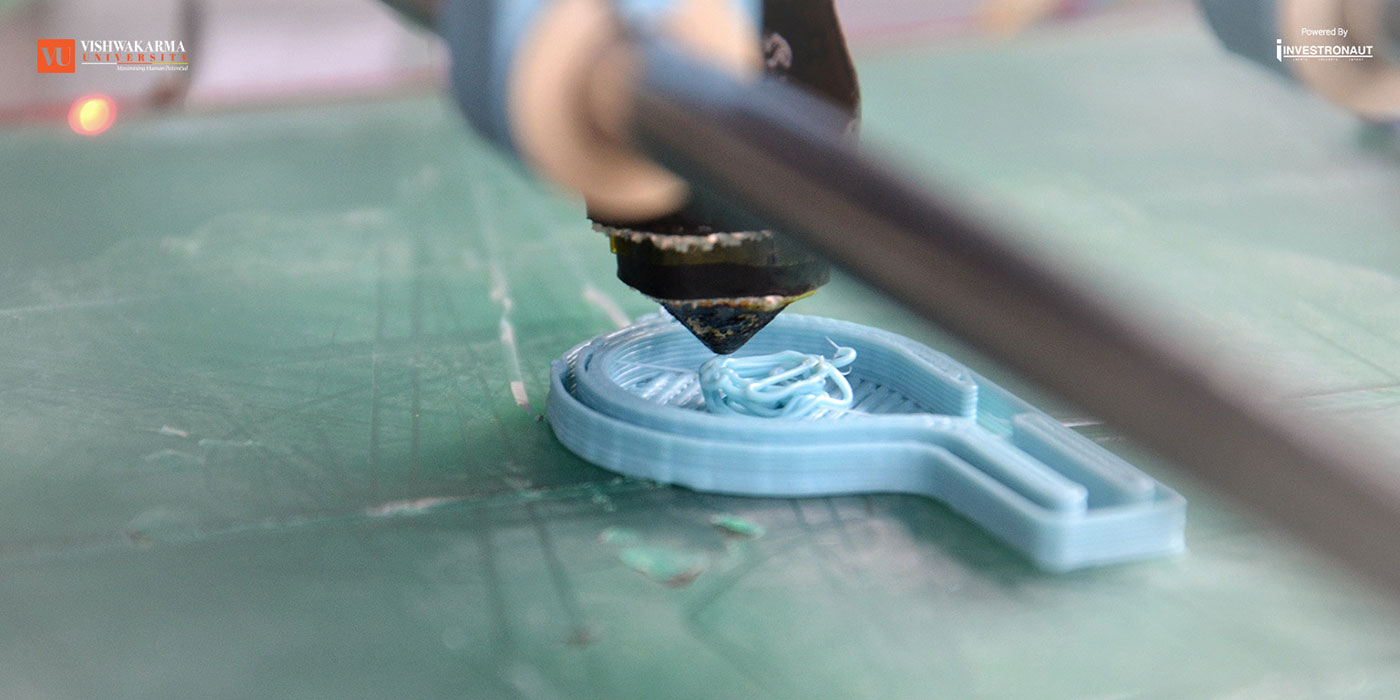

Additive manufacturing, also known as 3D printing, is a process that creates a physical object from a digital design. Additive manufacturing uses computer-aided-design (CAD) software or 3D object scanners to direct hardware to deposit material, layer upon layer, in precise geometric shapes. As its name implies, additive manufacturing adds material to create an object.

How does additive manufacturing work?

The term “additive manufacturing” is a technology that produces three-dimensional objects, one superfine layer at a time. Each successive layer bonds to the preceding layer of melted or partially melted material. It is possible to use different substances for layering material, including metal powder, thermoplastics, ceramics, composites, glass and even edibles like chocolates.

Objects are digitally defined by computer-aided-design (CAD) software that essentially slice the object into ultra-thin layers. This information guides the print head as it precisely deposits material upon the preceding layer. Or, a laser or electron beam selectively melts the bed of powdered material to form a layer. As materials cool, they fuse together to form a three-dimensional object.

The journey towards these 3D object is revolutionising manufacturing. Gone are the intermediary steps, like the creation of moulds or dies, that cost time and money

Additive manufacturing advantages

The strengths of Additive Manufacturing lie in those areas where conventional manufacturing has its limitations. The technology is of interest where a new approach to design and manufacturing is required so as to come up with solutions. It enables a design-driven manufacturing process - where design determines production and not the other way around.

What is more, Additive Manufacturing allows for highly complex structures which can still be extremely light and stable. It provides a high degree of design freedom, optimisation and integration of functional features, the manufacture of small batch sizes at reasonable unit costs and a high degree of product customisation even in serial production.

When compared to the relative tedium of traditional manufacturing, AM offers a more dynamic, design-driven process.

Complex geometries

The technology enables engineers to design parts that incorporate complexity that is not possible using other methods. Intricate features can be incorporated directly into a design. Parts that previously required assembly and welding can now be produced as a single part, which makes for greater strength and durability. Designers are no longer restricted to the limitations of traditional machines and can create parts with greater design freedom.

Time saving

Parts are manufactured directly from a 3D CAD file, which eliminates the cost and lengthy process of having fixtures or dies created. Plus, changes can be made mid-stream with virtually no interruption in the process. Since AM has adapted to the digital-to-digital process, it eliminates traditional intermediate steps and it is possible to make alterations on the run.

Weight saving

In designing everything from bridges to skyscrapers, engineers have long sought to minimise weight while maximising strength. By incorporating organic structures into designs, designers can eliminate substantial weight while maintaining the part’s strength and integrity. With additive manufacturing, designers realise the dream of utilising organic structures to greatly reduce the weight of objects.

The voice behind this article is Ashwini Gaikwad,Content Writer, Investronaut.